Spanner wrenches are indispensable tools that bridge the gap between mechanical finesse and practicality. In this content, we’ll focus on understanding the several uses of the spanner wrench and explore alternative solutions that keep the wheels of innovation turning.

Table of contents

What Is A Spanner Wrench?

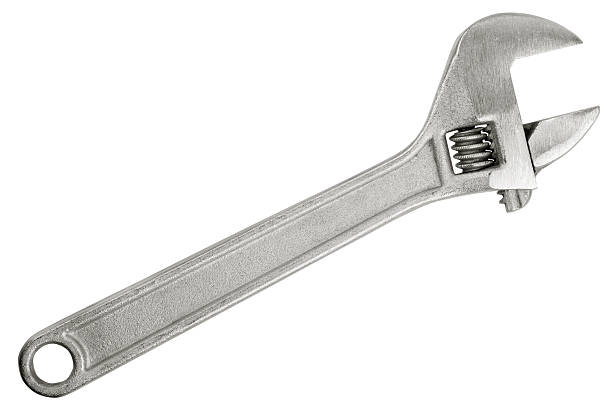

A spanner wrench is a specialized hand tool designed for turning fasteners with a series of pins or hooks that engage corresponding notches, holes, or lugs on objects like nuts, bolts, or collars. This versatile tool provides a secure grip, allowing precise application of torque. Spanner wrenches come in various designs to suit different fastener types and sizes, making them indispensable in maintenance, repair, and assembly tasks across various industries.

Types Of Spanner Wrench

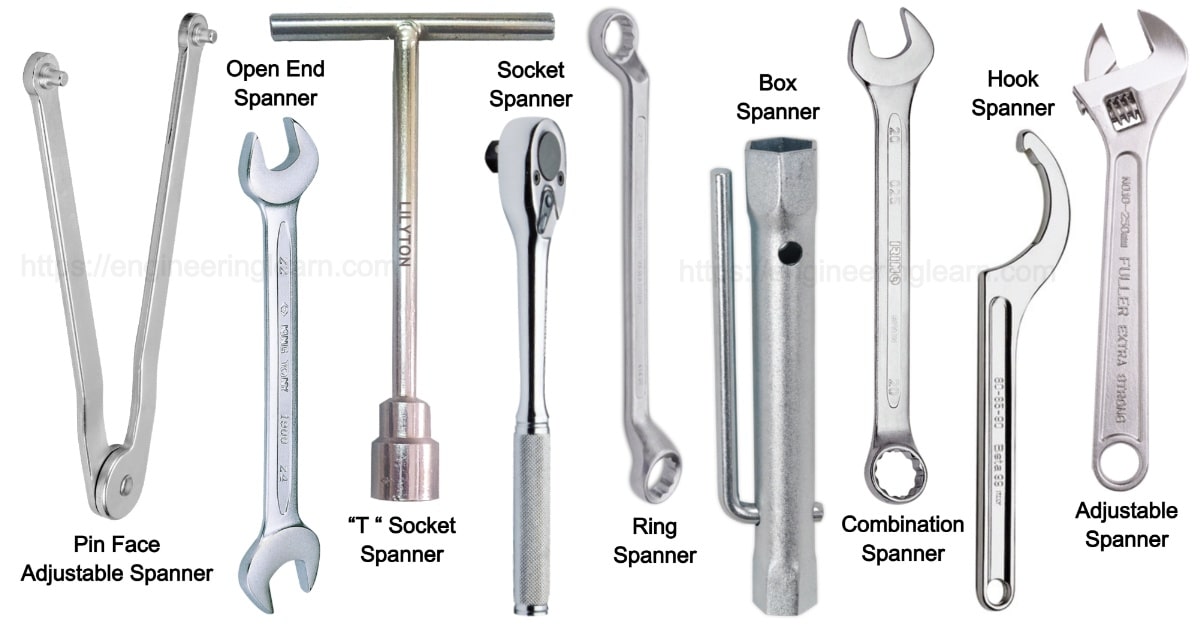

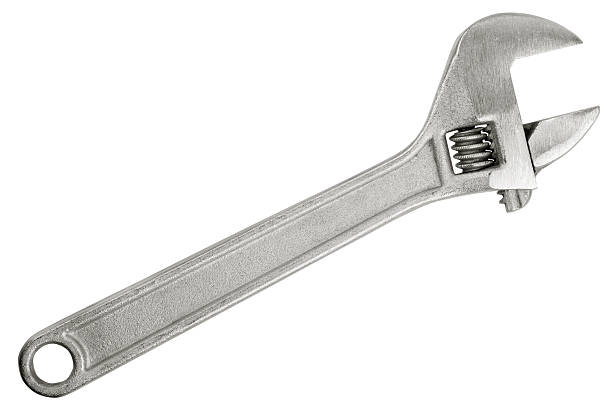

- Adjustable Spanner Wrench: Features an adjustable jaw, allowing it to accommodate different sizes of fasteners.

- Hook Spanner Wrench: Equipped with a hook-like projection to engage slots or holes on collars, locknuts, or bearing nuts.

- C-Wrench: Resembles the letter ‘C,’ with one fixed jaw and an adjustable jaw, suitable for various nut sizes.

- Pin Spanner Wrench: Utilizes two or more pins to fit into holes or notches on a fastener, providing a secure grip.

- Face Spanner Wrench: Has smooth, flat jaws that engage with the flat surfaces of collars or nuts, preventing damage.

- Hammer Wrench: Designed with a striking surface on one end, allowing for additional force to be applied when needed.

- Single-End Spanner Wrench: Features a single hook or pin for engaging with specific fasteners.

- Double-End Spanner Wrench: Equipped with different types of engaging elements on each end, providing versatility.

- Plumber’s Wrench: Specifically designed for plumbing applications, with a jaw that can grip pipes securely.

- Ratcheting Spanner Wrench: Incorporates a ratcheting mechanism for more efficient use in confined spaces.

Uses Of Spanner Wrench

A spanner wrench is used for:

- Nut Tightening and Loosening: Primary use is for turning nuts and bolts securely during assembly or disassembly.

- Machine Repair: Essential for maintenance tasks on machinery where precision torque is required.

- Automotive Work: Commonly used for tasks like adjusting suspension components, tightening bolts in engines, and more.

- Plumbing Applications: Ideal for tightening or loosening pipe fittings and various plumbing connections.

- Bearings and Hubs: Useful for adjusting or replacing bearings and hubs in mechanical systems.

- Construction: Employed in construction work for tightening or loosening nuts and bolts in structural elements.

- Appliance Repair: Valuable for repairing household appliances that have fasteners requiring precise torque.

- Bicycle Maintenance: Used in adjusting components like bike pedals, bottom brackets, and other fasteners.

- Electronic Equipment: Applied in delicate tasks involving electronics where a precise grip is necessary.

- Industrial Manufacturing: Vital for various tasks on the production line, ensuring accurate and secure fastening of components.

How To Use A Spanner Wrench?

To use a spanner wrench:

- Select the Right Spanner Wrench: Choose the appropriate type and size of spanner wrench for the fastener you are working on.

- Position the Wrench: Align the engaging elements of the spanner wrench with the notches, holes, or lugs on the fastener.

- Adjust if Necessary: If using an adjustable spanner wrench, ensure it is set to the correct size for a snug fit on the fastener.

- Apply Pressure: Hold the spanner wrench securely and apply steady pressure in the direction needed (clockwise for tightening, counterclockwise for loosening).

- Use Proper Technique: For maximum leverage, position the handle in a way that allows you to apply force comfortably and efficiently.

- Avoid Over-tightening: Exercise caution to avoid over-tightening, especially with delicate or precision components.

- Inspect for Damage: After use, inspect the spanner wrench for any signs of wear or damage. Replace or repair as needed.

- Store Properly: Keep your spanner wrench in a dry and clean environment, and store it securely to prevent damage and ensure longevity.

Alternatives Of Spanner Wrench

Adjustable Wrench: Offers versatility for various sizes of nuts and bolts but may not provide the same precision as a spanner wrench.

Socket Wrench: Excellent for turning nuts and bolts and often comes in sets with various socket sizes for different applications.

Pliers: Can be used for gripping and turning, especially in situations where a spanner wrench might not fit.

Pipe Wrench: Suitable for larger pipes and plumbing tasks, providing a strong grip but may not be ideal for precision work.

Box Wrench: Double-ended wrench with enclosed heads, providing a secure grip on nuts and bolts.

Adjustable Jaw Pliers: Offers an adjustable jaw for gripping various sizes of fasteners, providing flexibility in use.

Monkey Wrench: Adjustable wrench with a straight handle, commonly used for plumbing tasks.

Hex Key (Allen Wrench): Ideal for hexagonal socket screws and bolts, providing a compact and precise alternative.

Crowfoot Wrench: Designed for use with a torque wrench, providing a different approach to accessing tight spaces.

Multi-Tool: Some multi-tools include wrench-like features and can serve as a compact alternative for basic tasks.

Frequently Asked Questions

While versatile, a spanner wrench may not completely replace other tools. It excels in tasks requiring a secure grip on fasteners, but for broader applications, alternatives like adjustable wrenches, pliers, or socket wrenches may be more suitable.

Yes, always wear appropriate personal protective equipment. Ensure the spanner wrench is the right size and type for the task, and use it with proper technique to avoid injury. Inspect the tool regularly for wear and tear.

Spanner wrenches are available at hardware stores, online retailers, and specialty tool shops. Check with local suppliers or major online platforms to find a variety of options.

Spanner wrenches are designed for specific types of fasteners, so it’s crucial to match the tool with the notches, holes, or lugs on the fastener. Using the wrong type may result in damage to the tool or the fastener.

Inspect the spanner wrench for wear or damage after each use. Keep it in a dry and clean environment. Store it securely to prevent damage and ensure longevity. Regular maintenance, such as lubrication, may be necessary for smoother operation.

Conclusions

The spanner wrench stands as a testament to the marriage of precision and practicality in the realm of hand tools. Its ability to securely grip and turn fasteners, coupled with a diverse range of designs catering to specific applications, makes it an indispensable ally in the hands of craftsmen and mechanics.

References

- wikipedia.org – Wrench

- redboxtools.com – SPANNERS VS WRENCHES: WHAT’S THE DIFFERENCE BETWEEN THEM IN THE UK?

- machineriespoint.com – What can I use instead of a spanner wrench – 6 Alternatives

Recommendations

- How Big is 10 Acres of Land? (Visual Examples for Comparison)

- How Many Months is 60 Days? (Explaining the Calculation Process)

- How Big is 5 Inches? 6 Items with Accurate Measurement

- How Long Are Menards Rebates Good For?

- How Tall Is All Might? Everything To Know About Hero Academia

- How Tall is Kevin Gates? Everything about the Rapper

- How Long Are HS Football Games? (Explained)

- How Tall is Trippie Redd? Everything About the Rapper